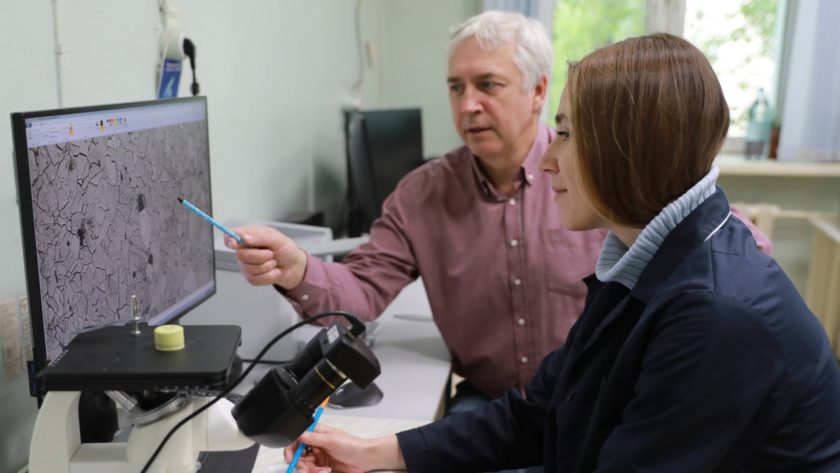

At the Mining and Chemical Combine (MCC) in Zheleznogorsk, Krasnoyarsk Krai, part of Russia’s state corporation Rosatom and its Environmental Solutions division, testing has begun on the steel that will be used to manufacture auxiliary equipment for the upcoming Experimental Liquid Salt Reactor (ELSR). The program and methodologies for the scientific and engineering research work have been developed by specialists from the combine in collaboration with researchers from Ural Federal University (UrFU) and the Institute of High-Temperature Electrochemistry of the Ural Branch of the Russian Academy of Sciences. Ural scientists are involved in this project as part of the Ural Interregional Research and Educational Center for Advanced Production Technologies and Materials.

Additionally, the university has supplied some equipment to the combine: two experimental setups are located at the former atomic thermal power plant on the combine’s premises. The first setup is designed for producing fuel salt based on lithium and beryllium fluorides. The second serves as a working area for conducting corrosion tests on structural materials used in the spent nuclear fuel processing module.

During the experiment, several tasks will be addressed: confirming the feasibility of using selected steel samples in the project; monitoring changes in the impurity composition of the salt due to corrosion of the samples (samples will be collected throughout the experiment); and testing methods for purifying the fuel salt. The steel samples will undergo 4,000 hours in an aggressive environment: in a molten salt mixture heated to nearly 700°C, containing the most radiotoxic elements from spent nuclear fuel—minor actinides.

“We are implementing all the developments from the participating institutions in this program. The entire range of work surrounding the ELSR undoubtedly holds practical interest, but what is most exciting is its novelty. Everything created around the ELSR will be new. Therefore, MCC, as the operating organization, must thoroughly explore all possibilities of the experimental liquid salt reactor, from preparing the fuel salt to selecting structural materials. However, the most crucial work lies ahead, correlating all obtained results with established goals and objectives,” noted Vladimir Matselia, director of the International Center for Engineering Competencies at MCC.

Once the experiment is completed, the steel samples will be extracted, deactivated, and necessary measurements will be taken to determine their mechanical and corrosion properties (in accordance with existing methodologies). Based on the results obtained, a conclusion will be drawn regarding whether this steel is suitable for manufacturing auxiliary equipment.

In late 2019, Rosatom began designing Russia’s first experimental liquid salt reactor to develop technology for burning long-lived components of irradiated fuel—minor actinides. The ELSR will operate on liquid fuel derived from a molten fluoride salt mixture containing plutonium as a fissile material along with minor actinides that need to be incinerated.

This text has been prepared based on information from Rosatom’s press service.